Ford Otosan produces 70% of Ford's Commercial Vehicles sold in Europe (except for Ranger and Transit Connect) and is the leading manufacturer of Ford Transits globally.

Being one of the most customizable commercial vehicles in the market, more than 1.500 variants of Transit is being produced.

Transit's model variability introduces a complex game of efficiency, as it is more productive to manufacture the same product consecutively, rather than accomodating for different specifications continuously along the schedule.

A rolling window of 5k Ford Transit orders are assigned at any moment. The faster you produce, the more you get to produce.

Fewer specification changes in the schedule means faster production. Producing A-B-A-B takes more time than A-A-B-B. Therefore, one of our objectives is to reduce the count of switches between specifications in the production schedule.

Not all vehicles require the same human effort, but all 8h shifts have the same amount of personnel. We require a production schedule that is as homogeneous as possible in terms of human effort required across all shifts it covers.

Some of our physical and empirical constraints include; No more than N many left side sliding doors in T minutes. No more than M many jumbos in an hour. Produce Jumbos in groups of N and busses in groups of M. Have a min of x many vans between groups of A

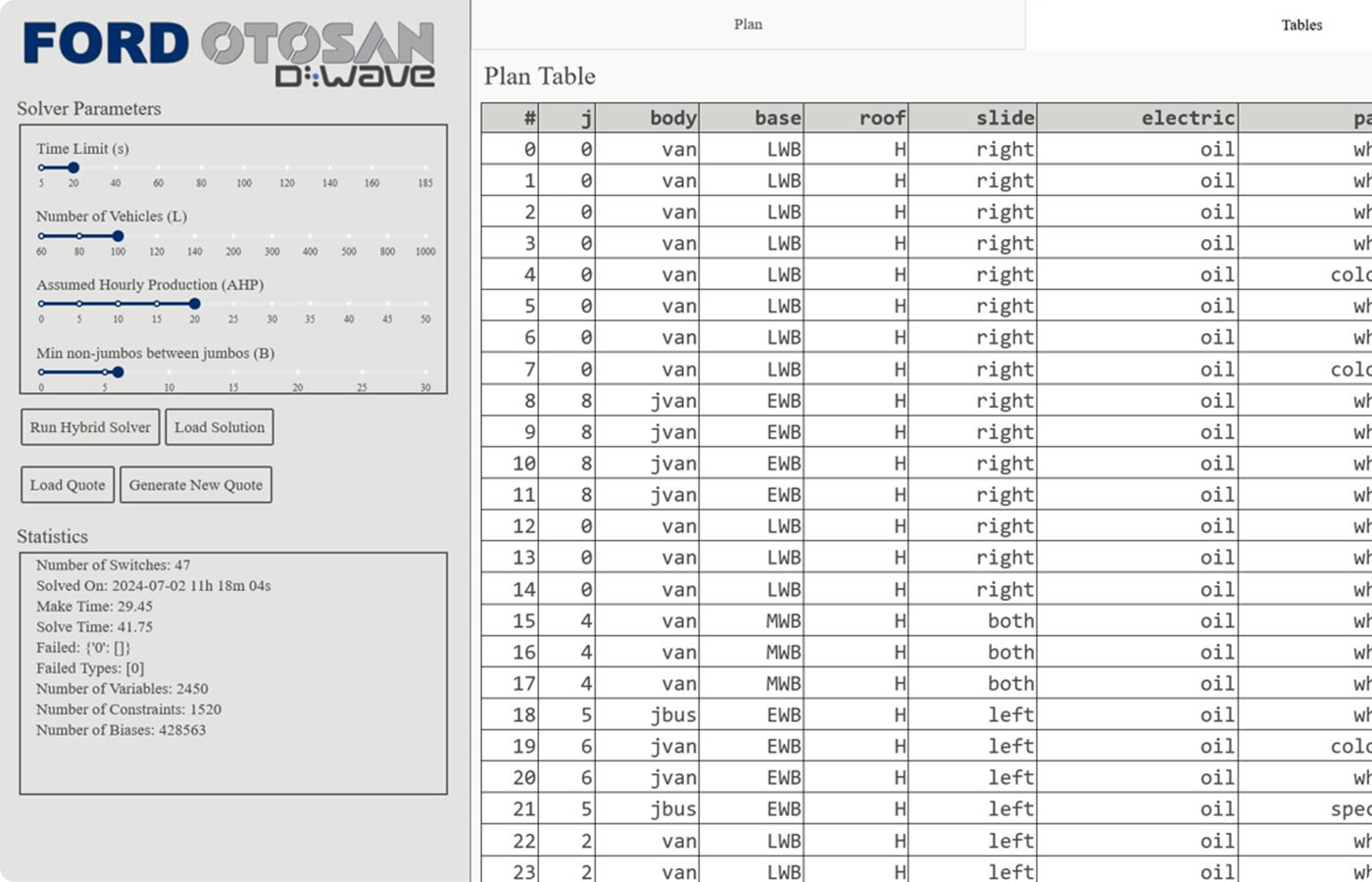

We have developed both Quantum and Classical solutions to minimize setup time and balance work loads across shifts. With the reduction in work load imbalances, we aim to minimize frequency of unplanned maintenance needs.

As longer schedules will be optimized, the uncertainties concerning our suppliers and thus our supply delays will be reduced. We predict to increase our production by 0.1 vehicles per hour at peak demand, utilizing this otherwise lost manufacturing time.

| Solver | Time | Switch Count | Scalability |

|---|---|---|---|

| Quantum | 3.3 Mins | 300+ | High |

| Proprietary Classical Solver | 10 Mins | 280+ | - |

| Open Source Solver (CBC) | 100 Mins | Agreeable | - |

Additional Boundary Conditions are required to knit together batches of vehicles to enlengthen the schedules.

D-Wave’s Hybrid Solver is used to take advantage of its high constraint capacity with a binary Constrained Quadratic Model.

Model variety effects number of variables and constraints heavily but on average ~15.000 constraints (< 100.000 limit) and ~25.000 variables (< 500.000 limit).

Physical Constraints

Work Balancing

Faster response time to unfavorable events that require rescheduling.

Taking advantage of the constraint limit, we intend to expand the problem (buffer area, paint shop, assembly).

Comparable cost to proprietary classical approaches.

Experiment with some of the parameters available to our planning experts through precomputed quantum annealing results.

Start Demo!

Activation of Quantum Scheduling at Gölcük Body Shop Transit vehicle line.

Optimization of Ford Custom vehicle production scheduling at Yeniköy Body Shop.

Extension of the optimization problem to both up and down stream processes; stamping, paint shop, assembly and buffer zones.

/